| Condition: | 500mm | Opening Stroke:: | Horizontal |

|---|---|---|---|

| Certification:: | ISO / CE | Power: | 50HZ |

| Machinery Test Report:: | Provided | Clamping Force: | 1800KN |

Standard Electrical Injection Moulding Machine

• Modular design good for many different applications.

• China unique producer central locking toggle, 1000+ market share on the world.

• Designed by Germany, the low- inertia injection unit achieves the high response and

high precision injection control.

• Low temperature plasticizing unit optimized by German improves. Plasticizing

efficiency and reduce energy consumption.

• High thrust and non noise ball screw with German technology.

• German high performance controller, industry 4.0 is within reach.

Essential details

| Model | 400T | 500T | 600T | |||||||

| Screw Specifications | A | B | C | A | B | C | A | B | C | |

| Screwdi ameter | mm | 65 | 75 | 80 | 70 | 75 | 85 | 75 | 85 | 90 |

| Screw L/Dratio | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 22 | |

| Theoretical injection volume | cm3 | 1C75 | 1431 | 1628 | 1481 | 1700 | 2184 | 1788 | 2297 | 2575 |

| Shot weight (PS) | g | 1C11 | 1345 | 1530 | 1377 | 1581 | 2031 | 1645 | 2113 | 2369 |

| injection rate(Ps) | g/S | 426 | 568 | 646 | G03 | 693 | 890 | G13 | 788 | 884 |

| Injection pressure | MPa | 242 | 182 | 160 | 209 | 182 | 142 | 204 | 159 | 142 |

| Inject on stroke | mm | 360 | 385 | 405 | ||||||

| Max. injection speed | mm/s | 156 | 166 | 157 | ||||||

| Screw speed | r/min | 0-200 | 0-200 | 0-200 | ||||||

| Sys. Pressure | MPa | 16 | 16 | 16 | ||||||

| Pump Motor(Min-Max) | kW | 75 | 94 | 101 | ||||||

| Displacement | ml/r | 100+100 | 125+125 | 160+125 | ||||||

| number of Motors | PC | 2 | 2 | 2 | ||||||

| Heater power | kW | 35 | 41 | 47 | ||||||

| Number oftemp. control zones | 5+1 | 5+1 | 5+1 | |||||||

| Clamping force | kN | 4000 | 5000 | 6000 | ||||||

| Opening stroke | mm | 900 | 1000 | 1150 | ||||||

| Tie bar distance W×L | mm*mm | 760x660 | 860x760 | 960x860 | ||||||

| Min. mold thickness | mm | 300 | 300 | 350 | ||||||

| Max. mold thickness | mm | 730 | 800 | 920 | ||||||

| Ejector stroke | mm | 190 | 210 | 210 | ||||||

| Ejector force forward | kN | 80 | 110 | 113 | ||||||

| Number of ejector bar | PC | 1+12 | 1+12 | 1+12 | ||||||

| Oil tank capacity | L | 680 | 850 | 940 | ||||||

| Machine dimensions(LxWxH) | m*m*m | 8.2x1.9x1.9 | 87x2.0x2.1 | 9.3x2.1x2.3 | ||||||

| Machine weight | Ton | 15 | 19 | 23 | ||||||

Main Features

Big: Bigger one size than other brand machines.

Precision: Products higher precision.

Save: Help customer save 2- 5% material.

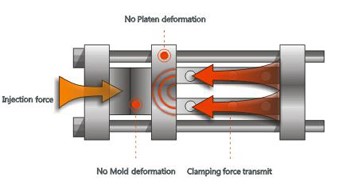

OUCO centre clamping structure

100% clamping force use.

Less possibility of flash, save flash trim work.

Save 2% - 5% material.

Offer good protection to mould, platens and tie bars.

Opening stroke 10 - 20% longer.

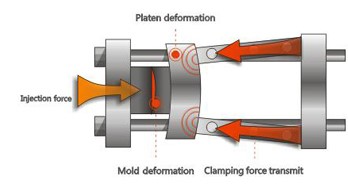

Traditional structure

With heavy clamping force waste, only 80 - 85% efficiency.

Moving platen with obvious deformation, cause flashes, wsaste of material and labor of trim the flashes.

Produced Products

![]()

![]()